Details

Output: 14 - 21,5 kW

Efficiency: 80%

CO emissions: 0.08%

Fine dust emissions: 30 mg/Nm³

Ecolabel: A⁺

Technical Data: PDF

Finishes

Standard burner finish

Woodchips | Vermiculite | Grey pebbles | White pebbles

Appliances with a 40 cm fireplace opening: Fitted as standard with white pebbles, or on request with grey pebbles or woodchips at no extra cost. Optionally available with Classic Style ceramic wood logs at additional cost.

Burner finish

SMOKE Style ceramic wood logs

If the optional log burner is ordered, ceramic logs will be supplied. Quantities depend on the burner measurement: if it is 50, 80 or 110 cm, 7, 10 or 14 logs are supplied.

Burner finish

CLASSIC Style ceramic wood logs

If the optional log burner is ordered, ceramic logs will be supplied. Quantities depend on the burner measurement: if it is 50, 80 or 110 cm, 13, 19 or 25 logs are supplied.

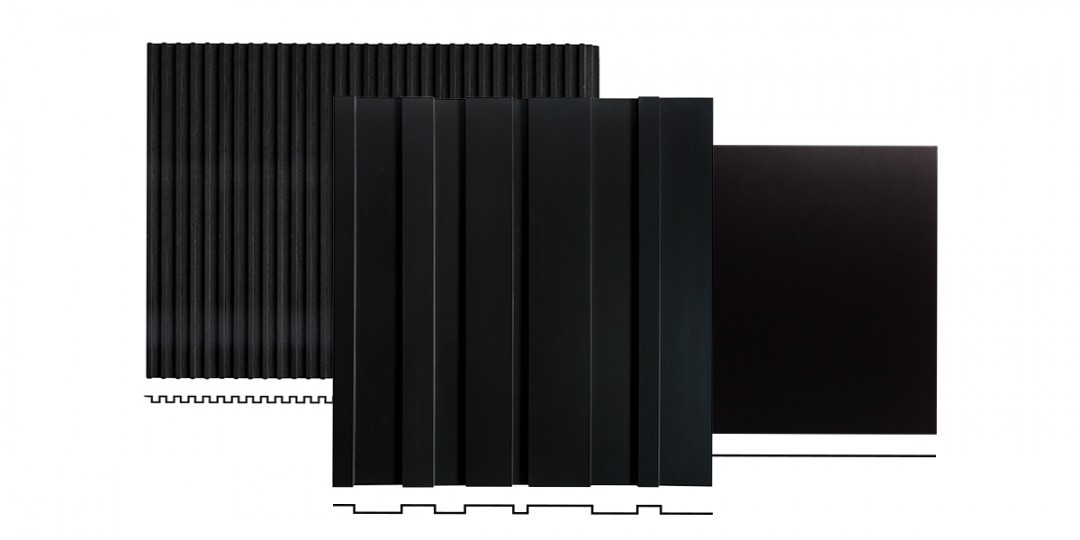

Interior finishing

Original | Design | Standard

Vertical ribbed cast iron slats (20mm)

Asymmetrical steel slats (10mm)

Flat steel plate (4 mm)

Interior finish 2021

Triangle | Round

Similar to the Original vertical cast iron ribs, the new Triangle and Round finishes ooze minimalism. However, whilst carrying on Metalfire’s love for pure and simple design, these innovative additions do add a certain dynamic to our range. The Triangle cast iron ribs offer a more angular approach to the fireplace’s interior, whereas the Round cast iron ribs - based on a design by Belgian architect Benoit Viaene - are characterized by soft curves. Common denominator: the elegant rhythm in both surfaces, which creates an interesting dialogue with the warm light of the fire. Irrefutably, both Triangle and Round are sleek and finely crafted finishes that will blend in seamlessly while simultaneously standing out in any (fireplace) interior.

Customizations

MADE-TO-MEASURE

Alongside its fireplace collection, Metalfire also specialises in additional MADE-TO-MEASURE solutions, finishing frames, concepts, floor plates, wood storage, etc. These items are manufactured to the design of the customer/architect/interior designer.

The technical department will submit the production plan to the customer for approval, and will then create these unique pieces through the skilled hands of the craftsmen in our workshop. This gives the products a unique appeal which simply can’t be achieved by automated production processes.

Finishing frames (90 x 10 mm) and concepts available in all standard versions and to measure.

Prices can be requested through our resellers.

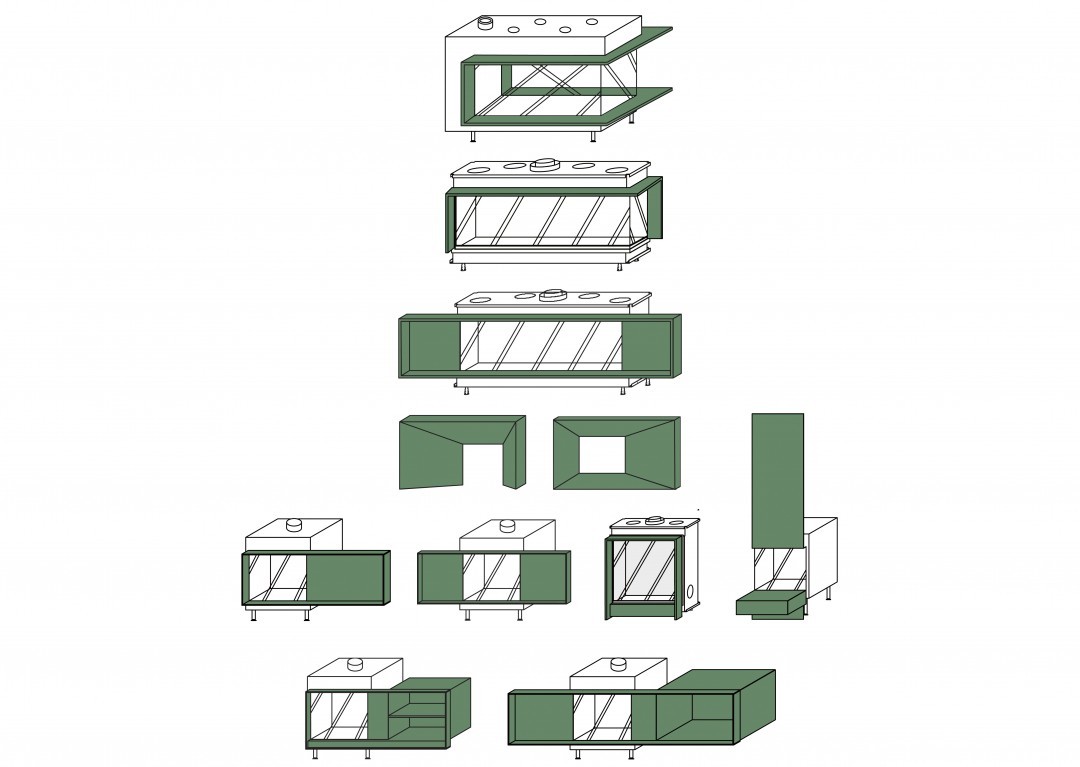

MF 600-50 WHE 1S

Ultime D

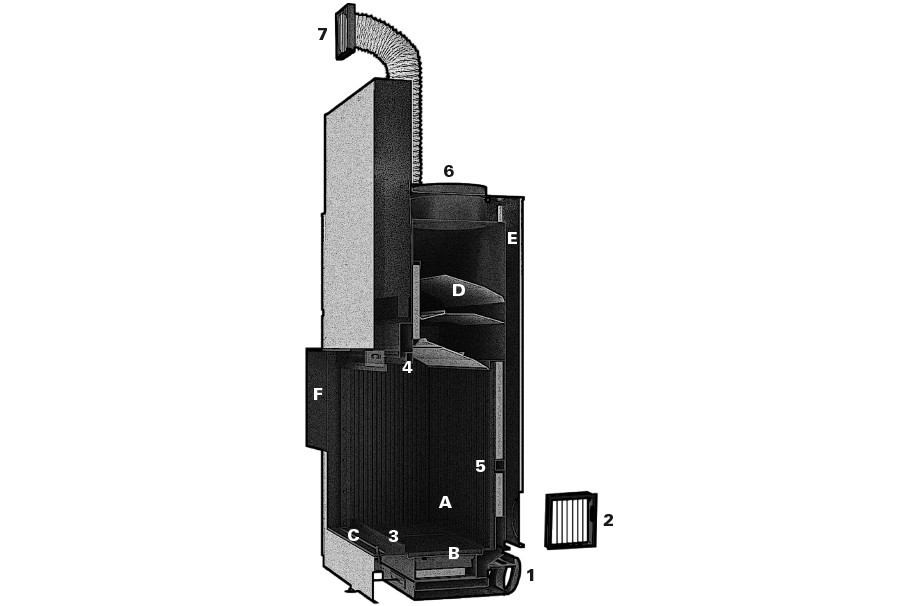

This generation of room air independent wood fireplaces with liftable door is equipped with a dynamic combustion technique that ensures optimal combustion and high efficiency. The appliances are independent of room air and are therefore suitable for all homes that are built according to the latest building regulations. A typical Metalfire product, with the most advanced technology.

Specifications

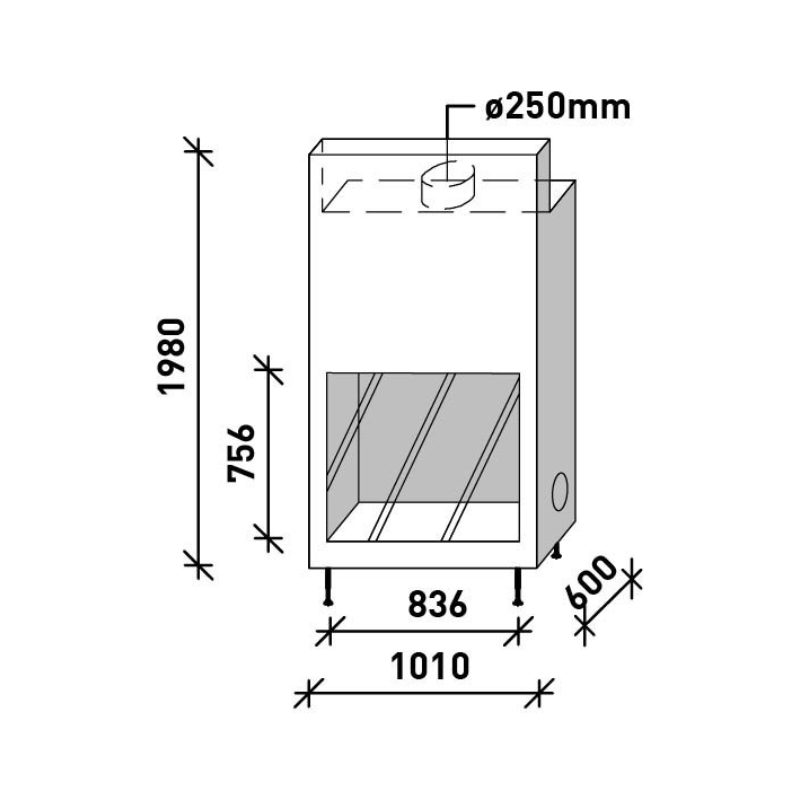

Supplies

- fresh air supply (connected below or behind)

- supply of ambient air/convection air

- primary air supply/combustion air

- secondary air supply/air flushing for glass

- tertiary air supply/post combustion

- flue gas discharge

- emission of heated convection air

Characteristics

A. insulated combustion chamber with ORIGINAL finish (vertical ribbed cast iron slats)

B. bottom plate in vermiculite or 10 mm flat steel with ashpan and cast iron grate

C. controls for air supply (primary, secondary and tertiary air supply)

D. adjustable flue gas baffle plates in stainless steel

E. guide for convection air through convection chamber

F. optional finishing frame in 10 mm solid steel

Sliding door system

To make it easy to make the fire or to add more wood, the glass door of the Ultime D 2s and 3s can be slid upwards. This is simple and easy thanks to the balanced door system and the handle supplied. The smart frameless finish to this door system ensures a handsome aesthetic finish that fits seamlessly into sleek interiors.

Easy-clean door system

All two and three-sided Ultime D models have a door system that allows the user to slide the glass upwards so that it is easily accessed for cleaning.

The glass can also by fully raised, making it easy to make the fire or add more wood.

Easy-clean door system

All one-sided Ultime D models have a door system that allows the user to tilt the glass forward so that it is easily accessed for cleaning.

The glass can also be fully raised, making it easy to make the fire or add more wood.

Removable handle

1. Ultime D 2S and 3S handle

This is supplied as standard for setting the combustion air supply as well as for the easy opening and closing of the door. To raise the door, the door latch can be slid into the door lifting plate provided.

2. Ultime D 1S handle

This is supplied as standard for setting the combustion air supply as well as for the easy opening and closing of the door. To raise the door, the door latch can be placed on the shaft provided. The reverse side of the handle can also be used for moving the grates. This is necessary when emptying the ashpan, which must be done regularly to maintain an optimal supply of combustion air.

Bottom plate

These bottom plates are made in heat-resistant vermiculite. This finish is only available for the Ultime D 2S and 3S models.

On application the Ultime D 2s or 3s can also be fitted with a cast iron bottom plate, at an additional cost.

Grate + ashpan

Standard for all 1S models. The cast iron grate is particularly attractive, and creates a real “fireplace look”.

The slots in the grate allow ash to fall into the ashpan. The ashpan itself can be easily cleaned by removing the grate and vacuuming the ashes using an ash vacuum cleaner. Alternatively, the ashpan can be removed from the fireplace for cleaning in another way.

Glass fibre seal

The seal, which is resistant to temperatures as high as 700°C, is mounted beneath the fireplace level with the bottom.

It provides better door closure so that the combustion chamber is fully sealed. Which in turns ensures optimal combustion and fewer harmful substances.

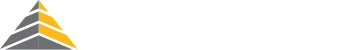

Positioning the fireplace

The fireplace is fitted with four adjustable feet.

These feet can be adjusted in height both internally and along the outer side of the fireplace.

If the highest foot position is insufficient, a supporting construction on which the fireplace can be placed must be installed.

This must be stable and strong enough to bear the weight of the fireplace.

Fuel: Wood

To obtain optimal combustion, the moisture content of the wood should be no more than 15% If this is not the case, the glass will quickly become soiled and appliance will be less efficient.

To achieve this moisture content, the wood must be dried for two to three years in a dry well-ventilated place. The most suitable wood types are beech, oak and birch. Each of our fireplaces

has an optimal wood load: for the Ultime D 600 and 800 models this is a maximum of four 25 cm logs with a total weight of 3.2kg. For the Ultime D 1050 and 1300 models the ideal load is a maximum

of three 30 cm logs with a total weight of 3.5kg. The use of resinous wood types, chipboard, laminate, treated wood or accelerants is strongly discouraged, as it produces sparks and a short burning time.

It also harms your fireplace and the environment.

Responsible wood burning

Wood heating can only be economical, healthy and ecological if it is used in the right conditions! Choice of equipment, choice of wood, feeding the stove, maintenance...

With these conditions you can reduce the emission of fine particles and other air pollutants, but also increase the efficiency of your combustion.

The objective is this: Increasing combustion efficiency Reduce emissions of fine particles and other air pollutants Improve end-user comfort.

To this end, a video is available today that explains all this step by step.